In a surprising turn of events, General Motors (GM) has found itself navigating the treacherous waters of production disruptions due to the recent impacts of Hurricane Helene. The automaker has ceased operations at two critical facilities that are central to their production of high-margin pickup trucks and SUVs. This situation underscores not only the vulnerability of automotive supply chains but also the heavy reliance of manufacturers on a network of suppliers that can be easily disrupted by natural disasters.

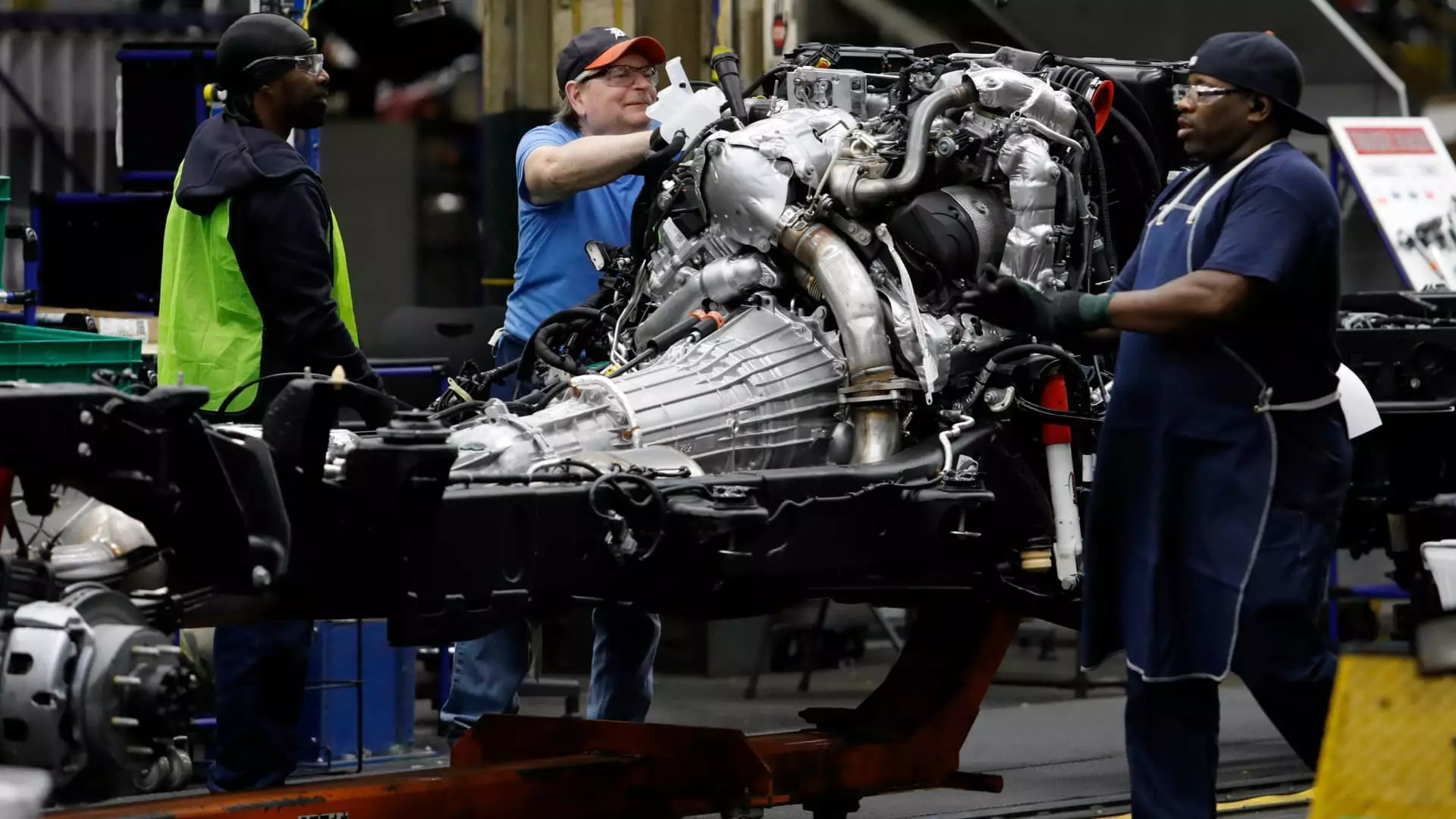

The two affected plants include Flint Assembly, located in Michigan, which is responsible for heavy-duty truck production, and Arlington Assembly in Texas, home to the manufacture of full-sized SUVs such as the Chevrolet Tahoe and Cadillac Escalade. The decision to halt production was made just ahead of scheduled shifts, indicating the urgency of the situation as suppliers struggled to recover from the hurricane’s effects. GM’s communication has been notably cautious; the company refrained from providing a specific timeline for when production might resume, reflecting uncertainty in the operational landscape.

Hurricane Helene made its mark along the southeastern U.S., leading to disastrous impacts that extended beyond immediate physical damage. The aftermath of the storm resulted in at least 215 fatalities, and recovery efforts are ongoing, illustrating the profound human and logistical challenges faced by affected regions. GM, in light of these developments, has expressed its commitment to working closely with impacted suppliers in an effort to restore normalcy while ensuring the safety of everyone involved. This reveals a critical aspect of the automotive industry: how closely intertwined it is with the broader economic and environmental factors that can lead to significant setbacks.

Jeffrey Morrison, GM’s vice president of global purchasing and supply chain, emphasized the lessons learned from previous disruptions, particularly during the COVID-19 pandemic. He pointed out that the company has since taken necessary steps to comprehensively map its supply chains, gaining better visibility into sub-tier suppliers and potential vulnerabilities. This proactive approach, regarded as a necessary evolution for the automaker, highlights an ongoing push to adapt to unanticipated challenges and improve overall responsiveness.

Morrison’s comments suggest a growing awareness in the industry about the need for resilience in supply chains, especially in light of recent challenges. By fostering deeper relationships with suppliers, GM aims to mitigate the impacts of future disruptions, whether they stem from natural calamities or labor strikes, which have also posed challenges to the company.

As GM grapples with the fallout from Hurricane Helene, the situation serves as a stark reminder of the fragile nature of supply chains in manufacturing. The automaker’s ongoing commitment to enhancing its supply chain transparency will be crucial in navigating these tumultuous waters. The broader implications for the automotive industry underpin the need for flexibility and preparedness in the face of unforeseen challenges, ensuring that companies can sustain operations while maintaining their commitment to safety and community well-being.